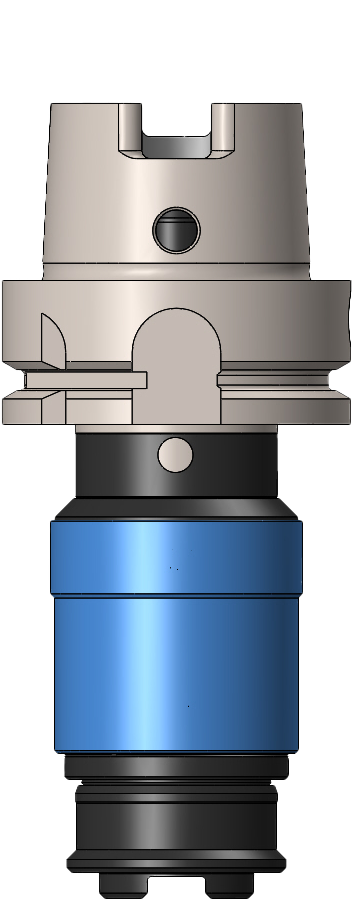

the best choice for rigid tapping

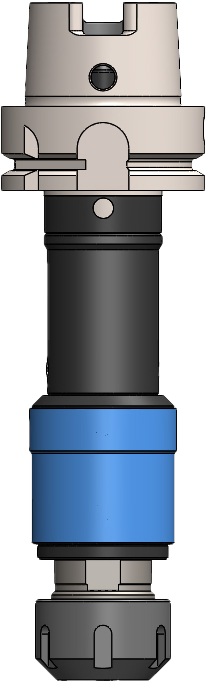

At the heart of SynchroFlex is a precisely machined flexure. It provides axial compensation for the unavoidable discrepancy between the machine spindle rotation, synchronized with the feed advance, and the actual tap pitch. By compensating for this error, thrust forces acting on the tap are dramatically reduced.The result is the longest possible tap life and much better quality threads.

At the heart of SynchroFlex is a precisely machined flexure. It provides axial compensation for the unavoidable discrepancy between the machine spindle rotation, synchronized with the feed advance, and the actual tap pitch. By compensating for this error, thrust forces acting on the tap are dramatically reduced.The result is the longest possible tap life and much better quality threads.

Unlike competitor tap holders that employ an elastomer ring to provide a small amount of axial compensation, the SynchroFlex® flexure has a consistent force vs deflection rate. This means consistently superior tap life and thread quality.

There is no torque transmitted through the flexure and the micro compression and extension  needed for synchronized tapping insures that the flexure is never overstressed. Left is an example of stress analysis at maximum compression. Millions of holes can be tapped without causing the flexure to fatigue, take a set, or wear out.

needed for synchronized tapping insures that the flexure is never overstressed. Left is an example of stress analysis at maximum compression. Millions of holes can be tapped without causing the flexure to fatigue, take a set, or wear out.

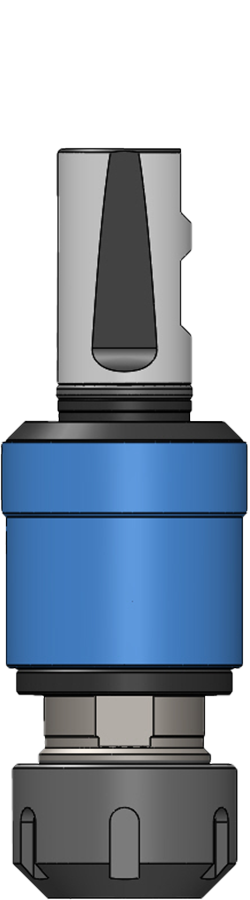

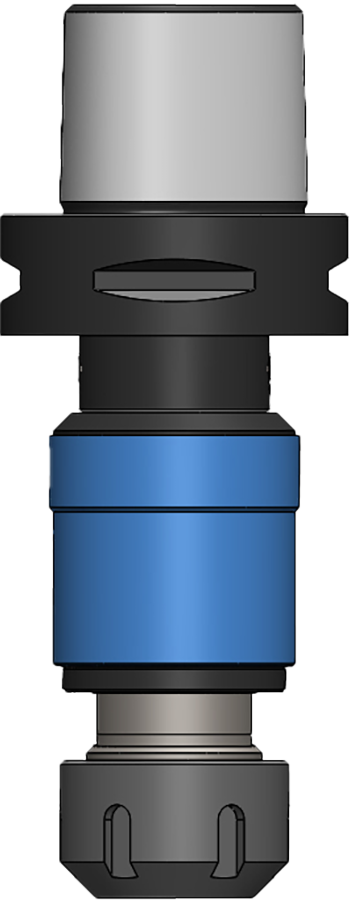

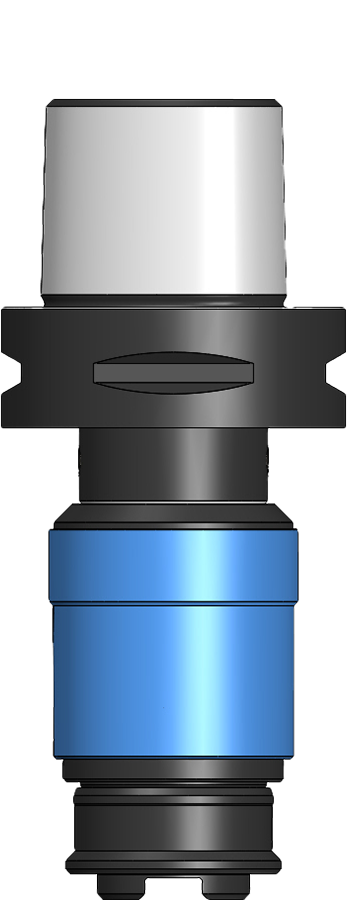

- Extended length tools for difficult to reach holes.

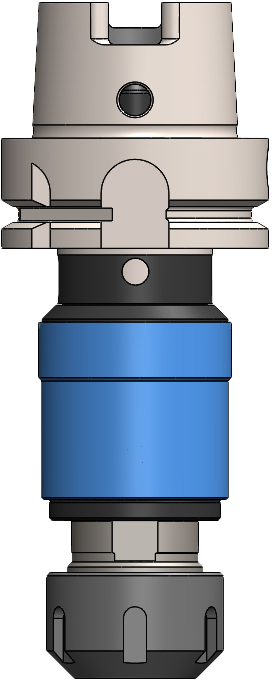

- Quick change for fast tap replacement without wrenches.

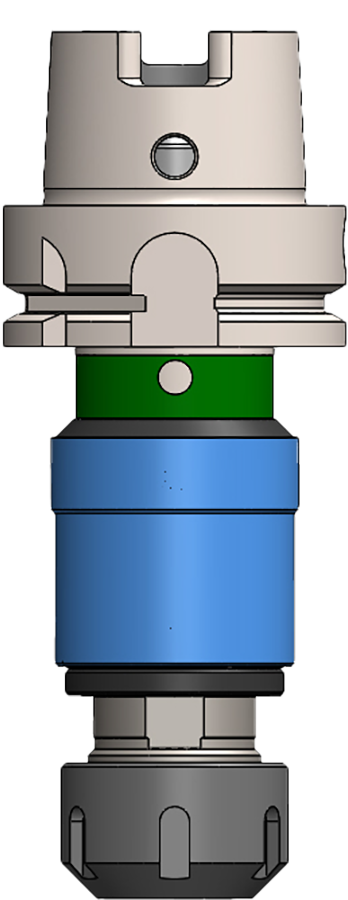

- Balanced high pressure, high flowrate internal coolant that has no effect on axial compensation.

- Minimum Quantity Lubrication (MQL).